HVAC

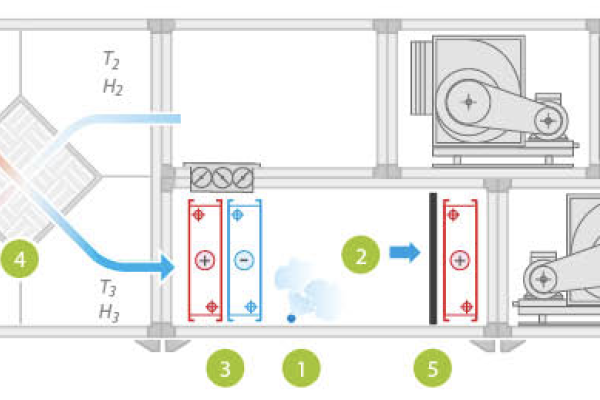

Current ventilation guidelines recommend maintaining ventilation with 100% outdoor air 24/7, or as much as possible if that is not feasible, as an effective way to keep airborne pathogen concentration under control. Obviously, outdoor air needs to be filtered and conditioned to guarantee the indoor temperature and humidity set points; this, in turn, implies a higher HVAC-related primary energy consumption, because more outdoor air needs to be conditioned compared to the pre-COVID-19 situation, when the flow of outdoor air was typically 20% of the total supply air entering the space.

Opened in fall 2018, the new $19.3 million school building spans 65,837 square feet with a capacity to serve 500 students. The building serves students of pre-school age through Grade Five and is also designed to host groups of various sizes during summer months. It also serves as the campus gateway to the adjacent Elkton Public Library and the Elkton Middle and High Schools.

[ Read Full Story ]

“Evaporative cooling capacity for the district system is provided by a six-cell, open-loop cooling tower capable of 6,000 tons,” said Reid Olsen, USU Central Energy Plant Manager, who has been at the university for 26 years. “This tower serves the condensers of the water-cooled chillers at the heart of the district cooling system. There are four chillers in all, two of which are rated for 1,800 tons each, and the other two are 900 tons apiece. The cooling towers reject heat from the condenser water loop via evaporative cooling, allowing the chillers to supply chilled water to the campus cooling loop.”

[ Read Full Story ]

Recent legislation is impacting the use of hydrofluorocarbon (HFC) refrigerants, both globally and nationally. On the heels of these changes is confusion about legislation and the availability of certain types of refrigerants. On a global scale, the Kigali Amendment to the Montreal Protocol provides a global phase-down schedule for the use of HFC refrigerants in multiple sectors - including R-134a and R-410A - for the HVAC/R industry. While ratified across the globe by approximately 100 countries to date, the amendment has yet to be ratified in the United States.

[ Read Full Story ]

In recent years, the HVAC industry has enlarged its vision from focusing on equipment efficiency measured in terms of ratings points at specific conditions to include a whole building perspective that uses models of year-long, real-world conditions. Accordingly, energy standards have adopted new rating methods to evaluate equipment efficiency during part-load operation. In Part 1 of this two-part article series we examined how these standards are evolving.

[ Read Full Story ]

Given that HVAC systems typically account for 44% of commercial buildings’ energy consumption1, HVAC optimization should be a priority efficiency upgrade after lighting improvements and other low-hanging fruit. Full-scale HVAC optimization typically reduces energy usage and costs by 20 to 40%, improves system reliability by operating equipment more efficiently and at optimal temperatures, ensures consistently healthy air quality and building comfort, and reduces a building’s carbon footprint.

[ Read Full Story ]

An airside economizer is typically used on a packaged rooftop or tied to an indoor AHU, allowing filtered outside air into the space when outdoor temperatures drop below 55°F (12 °C) (the common supply air temperature of indoor spaces) thus alleviating the need for the refrigeration cycle to be running. Interior space is being cooled yet the refrigeration system is not running, hence the name Free Cooling.

[ Read Full Story ]

Commercial buildings in the United States will be looking to replace centrifugal chillers as many are near or past their median replacement life of 25 years. This becomes apparent when you consider nearly half of all commercial buildings were constructed before 1980 according to data from the U.S. Energy Information Administration. The same can be said of buildings on American college campuses, which according to the same data, more than half of which were built before 1990. Bottom line — if you’re a commercial building owner or a facility manager/director in the United States, you may need to replace a chiller.

[ Read Full Story ]

The demand for advanced computing power rises year after year, but the more powerful the system, the more heat it generates. As data centers grow, they place higher demands on cooling equipment. Packing as much kilowatt and computer usage into as small a space as possible is key to reducing the cost and size of the facility. In doing this, data centers increase the power density of their systems, drawing more power, and generating more heat per unit area.

[ Read Full Story ]

Heat recovery opportunities have resulted in the largest amount of savings of our common projects our industrial energy management teams have implemented. It is not the easiest type of project to implement but the amount of savings and the reduction of emissions makes this project very worthwhile.

[ Read Full Story ]